Snacks Packaging Foil Film Custom Printed Aluminum Plastic Laminating Roll Film For Chip

Products Details

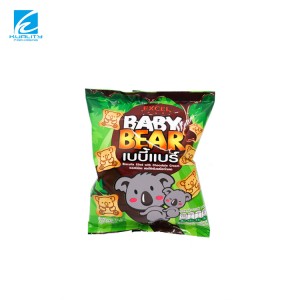

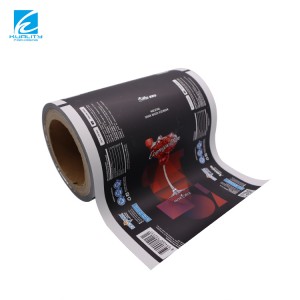

Potato chip packaging bags are often used in back seal bags. Compared with other packaging forms, the back sealing bag has no edge sealing on both sides of the bag body, which ensures that the pattern on the front of the packaging is complete and more beautiful. At the same time, in terms of layout design, the bag body pattern can be designed as a whole, which can maintain the coherence of the picture. And because the seal is on the back, the sides of the bag can withstand greater pressure, reducing the possibility of package damage. Moreover, packaging bags of the same size are back-sealed to minimize the total length of the seal, which also reduces the probability of seal cracking to a certain extent. The back-sealed bag can be filled with nitrogen to prevent chips from being crushed in transit. Therefore, the packaging of bagged potato chips is generally carried out by a nitrogen-filled potato chip packaging machine on the market. The commonly used materials for potato chip bags are BOPP/VMOPP/LDPE, etc. BOPP is used as the outer material because of its good printability, good gloss, good comprehensive front and moderate price. Therefore, the back seal bag is a common packaging in the field of snacks.

We are a packaging manufacturer with over 20 years of experience, with four world-leading production lines. We can design and customize suitable products for customers free of charge according to the needs of customers, and we must ensure your satisfaction. To order, please contact us, welcome to inquire.

Features

·Exquisite packaging

·High material thickness

·High sealing

Application

Material

Package & Shipping and Payment

FAQ

Q1. Are you a manufacturer?

A: Yes, we are. We have more than 20 years experience in this filed. Owing hardware workshop, helping purchase time and costs.

Q2. What sets your products apart?

A: Compared with our competitors: first, we offer higer quality products at an affordable price; second, we have a large client base.

Q3. How long is your delivery time?

A: Generally speaking, the sample will be 3-5 day, bulk order will be 20-25 day.

Q4. Do you provide samples first?

A: Yes, We can provide samples and customized samples.

Q5. Can the product be well packed to avoid damage?

A:Yes, The package would be standard export carton plus foam plastic, passing 2m box falling test.